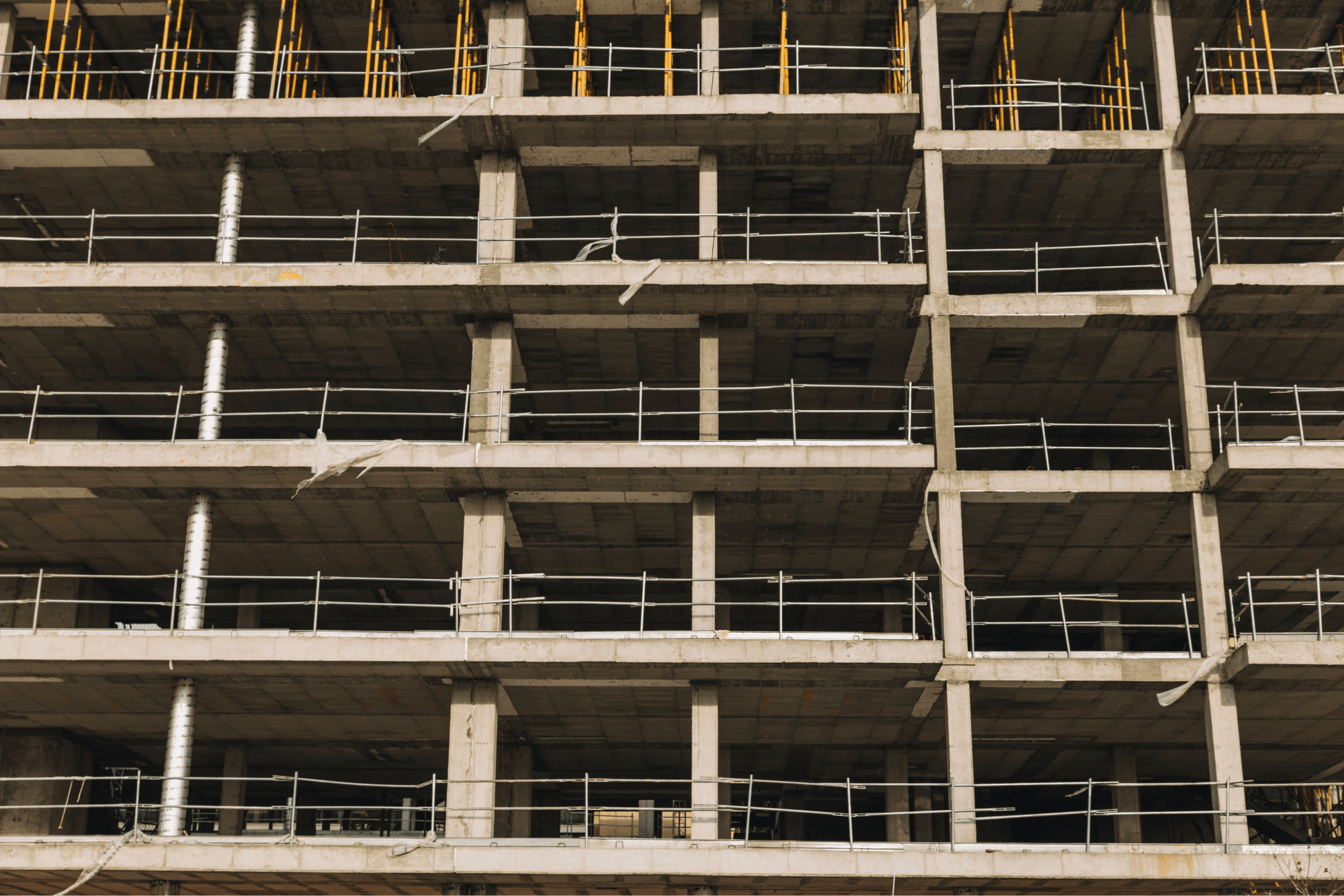

Building material testing

Building material testing is crucial for ensuring the quality, safety, and compliance of construction materials used in various building projects. Similar to oil testing, building material testing involves several key components:

-

Sampling and Collection

The process begins with the careful sampling and collection of building materials from different sources and stages of production. Representative samples are essential for accurate analysis.

-

Physical Properties Testing

Determining key physical properties such as strength, density, durability, thermal conductivity, and moisture content provides insights into the material's characteristics and performance in construction applications.

-

Chemical Composition Analysis

Testing for the chemical composition involves identifying and quantifying specific compounds present in the building materials. This analysis ensures adherence to regulatory limits and standards and helps assess product quality and safety.

-

Contaminant Detection

Rigorous testing is conducted to identify and quantify

-

Reliability

Ensures uninterrupted operations.

-

Insurance Compliance

Meets requirements for coverage.

-

Peace of Mind

Provides reassurance about system safety and performance.

, including

harmful chemicals, heavy metals, and pollutants. Detection of contaminants is

crucial for ensuring the safety and environmental sustainability of building

materials.

-

Stability and Durability Testing

Assessing the stability, durability, and resistance of building materials to various environmental factors such as weathering, corrosion, and aging is vital. This testing helps determine the material's lifespan, maintenance requirements, and suitability for specific applications.

-

Fire Resistance and Safety Testing

Building materials undergo testing to evaluate their fire resistance, flame spread, smoke generation, and toxicity. Compliance with fire safety regulations is essential for protecting occupants and property in case of fire incidents.

-

Structural Performance Testing

Testing structural materials such as concrete, steel, and timber involves assessing their load-bearing capacity, elasticity, and deformation behavior. This ensures structural integrity and safety in building construction.

-

Environmental Impact Assessment

Evaluation of the environmental impact of building materials, including their carbon footprint, energy efficiency, and recyclability, helps promote sustainable construction practices and green building initiatives.

-

Compliance with Building Codes and Standards

Building material testing is designed to meet and exceed regulatory requirements set by building codes, standards organizations, and government agencies. Adherence to standards is crucial for obtaining building permits and ensuring the safety and quality of construction projects.

-

Quality Control in Construction

Continuous monitoring of building material quality during construction activities is essential for detecting defects, inconsistencies, and deviations from specifications. Quality control measures help prevent construction failures, delays, and costly rework.

Benefits of Building Material Testing

-

Quality Assurance

Building material testing ensures that construction materials meet specified quality standards, leading to safe, durable, and reliable building structures.

-

Compliance and Regulatory Approval

Rigorous testing helps construction companies adhere to building codes, regulations, and standards, facilitating regulatory approval and project acceptance.

-

Risk Mitigation

Identification of material defects, weaknesses, and hazards during testing allows for proactive risk management measures, reducing the likelihood of construction accidents, failures, and liabilities.

-

Safety and Occupant Health

Thorough testing contributes to the creation of safe and healthy indoor environments by ensuring that building materials are free from harmful substances, emissions, and hazards.

-

Cost Efficiency

Cost Efficiency By identifying quality issues early in the construction process, building material testing helps prevent costly rework, repairs, and litigation, leading to overall cost savings and project success.

Water testing is a crucial process aimed at assessing the quality and safety of water for various purposes, including drinking, recreational activities, industrial use, and environmental

Read MorePharmaceutical raw material testing is a critical phase in the pharmaceutical manufacturing process, playing a pivotal role in guaranteeing the safety, efficacy, and quality of the final drug

Read MoreMedical device testing is a thorough process conducted to verify the safety, reliability, and regulatory compliance of medical devices. It involves assessing the performance, usability

Read MoreCosmetic testing is a comprehensive process that involves various laboratory analyses to assess the safety, quality, and sensory attributes of cosmetic products. These analyses encompass

Read MoreHerbal products, derived from plant sources, are subject to rigorous testing to ensure their safety, quality, and compliance with regulations. Testing focuses on various aspects, with a key emphasis

Read MoreEnvironmental testing is a comprehensive process designed to assess how a sample, be it a product or material, responds to various stressors and conditions that it might encounter during its

Read MoreFood Testing Is A Crucial Component Of The Food Industry, Aimed At Verifying The Safety, Quality, And Compliance Of Food Products With Established Standards And Regulations. It

Read MoreOil Testing Plays A Crucial Role In Maintaining Product Quality And Compliance With Safety And Environmental Standards. From Refining To Distribution, The Process Of Oil Testing Involves

Read MoreElectrical testing refers to a series of evaluations and assessments conducted on electrical components, systems, and devices to ensure their safety, reliability, and performance. These tests are designed to verify compliance with industry standards, regulatory requirements, and specific performance criteria.

Read MoreMechanical Testing In various industries, Mechanical testing plays a pivotal role in ensuring the quality and reliability of materials and products. From manufacturing to construction, Mechanical testing encompasses several essential components

Read More