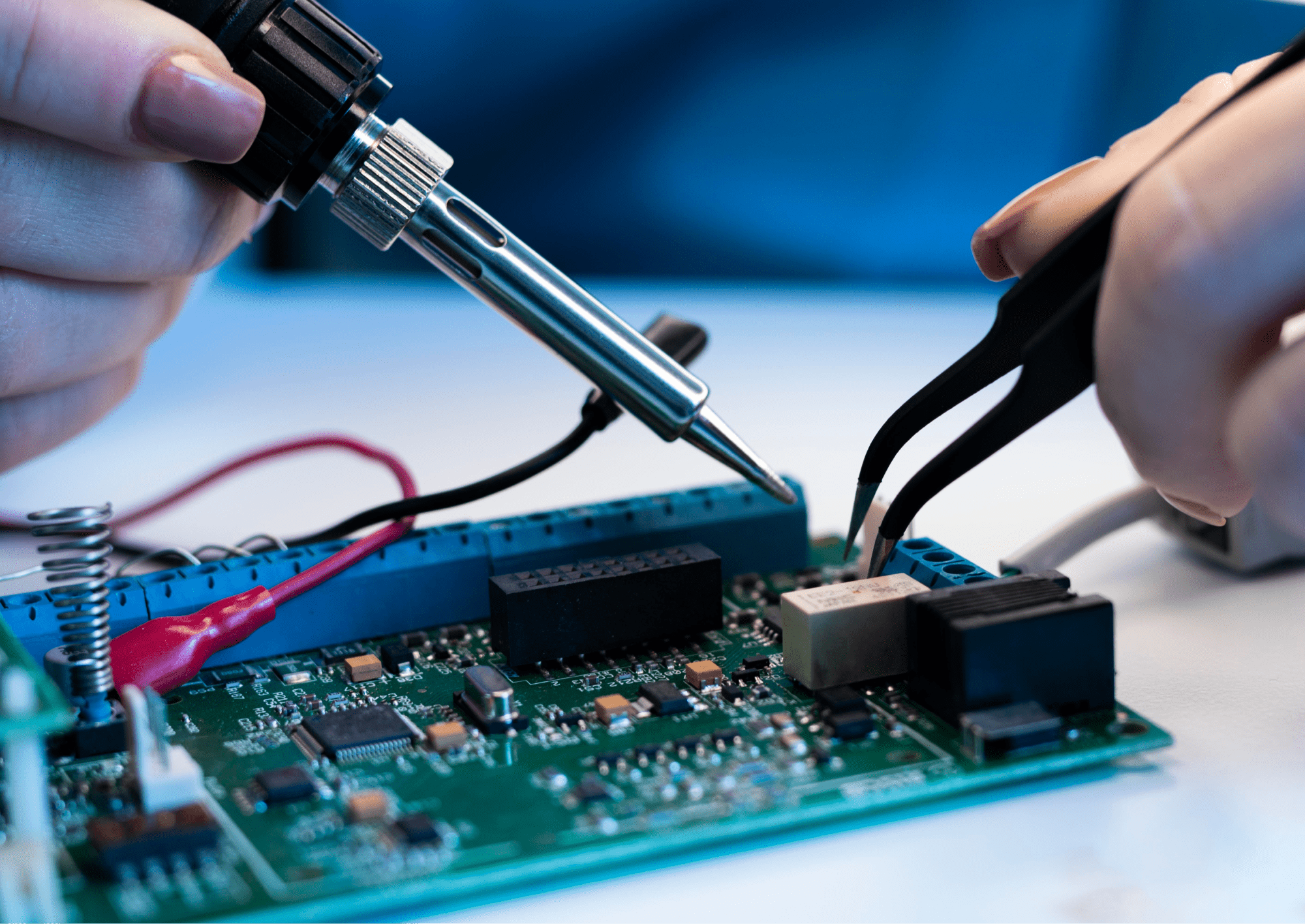

Electrical Testing

Electrical testing refers to a series of evaluations and assessments conducted on electrical components, systems, and devices to ensure their safety, reliability, and performance. These tests are designed to verify compliance with industry standards, regulatory requirements, and specific performance criteria. The below given are several essential components :

-

Product Sampling and Preparation

The foundation of accurate electrical testing lies in meticulous sampling and preparation of electrical components. Representative samples are carefully selected from production batches and prepared according to standardized procedures to ensure the accuracy and reliability of test results.

-

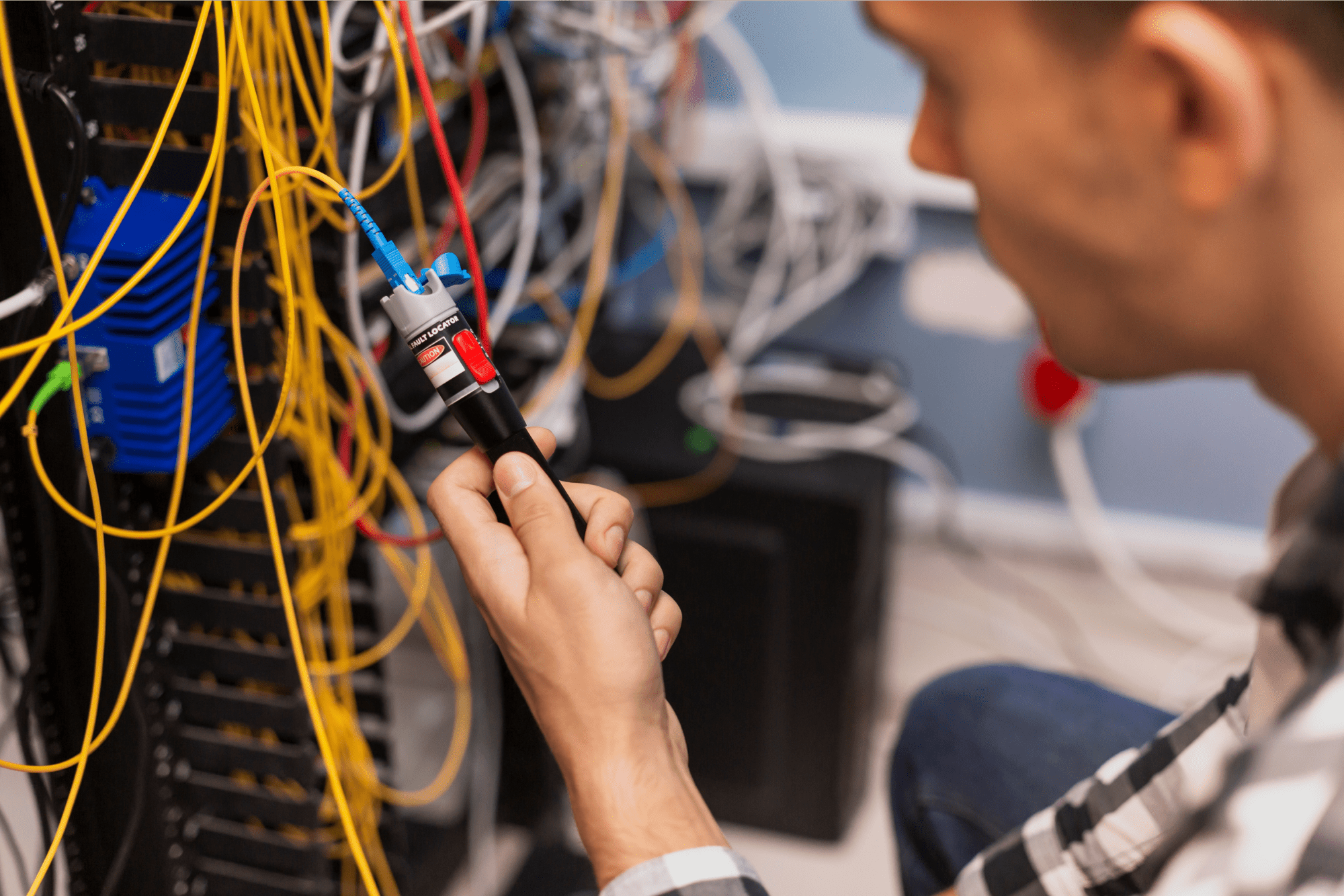

Functionality and Performance Testing

Functionality and performance tests evaluate the operational characteristics and efficiency of electrical components and systems under various operating conditions. These tests verify compliance with specified performance requirements and ensure optimal functionality in real-world applications.

-

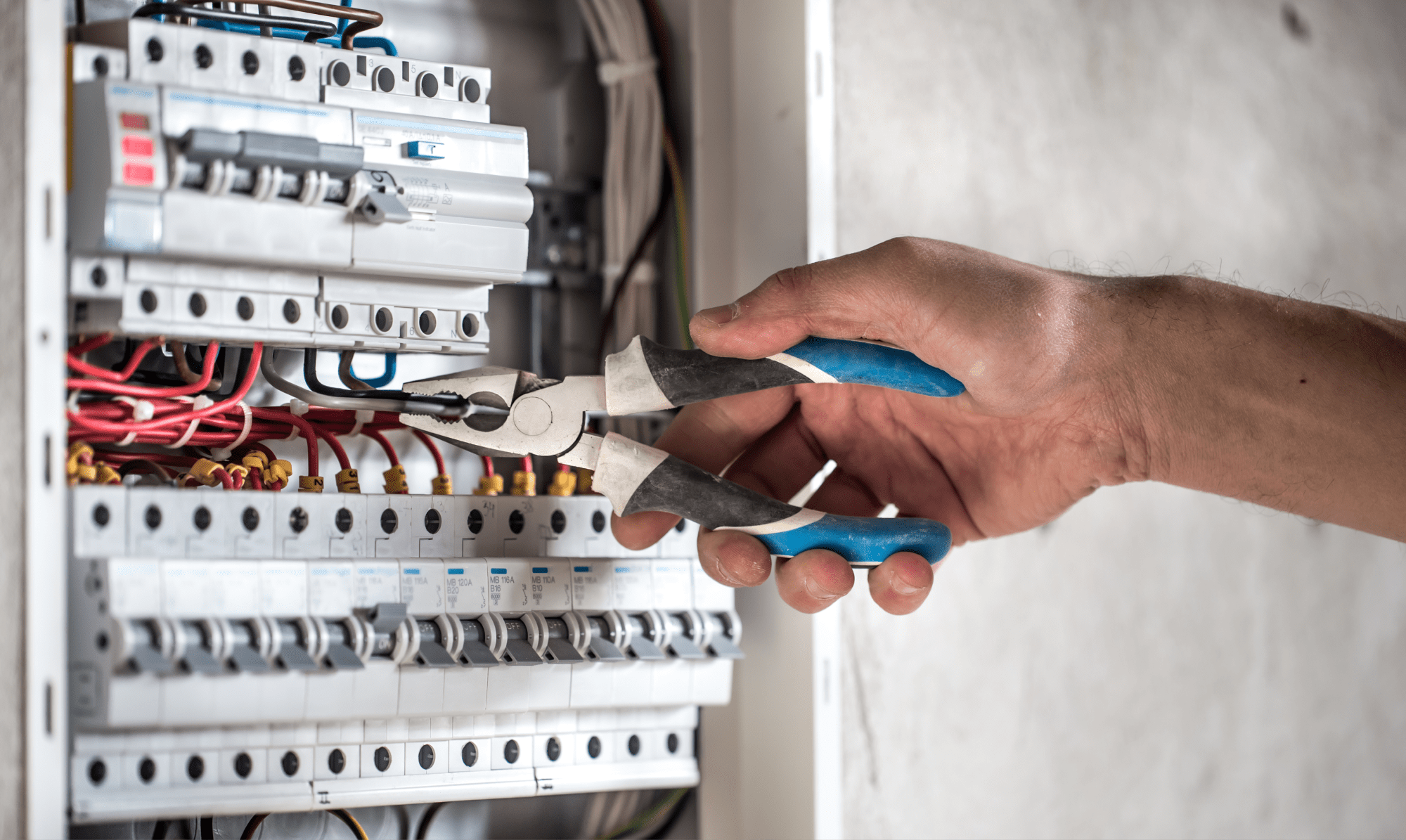

Insulation Resistance Testing

Insulation resistance testing assesses the electrical insulation properties of components and systems to detect potential faults or defects. By measuring the resistance to current flow across insulating materials, this testing helps identify insulation degradation and prevents electrical failures or safety hazards.

-

Dielectric Strength Testing

Dielectric strength testing evaluates the electrical insulation strength of materials by subjecting them to high voltage stress. This test assesses the material's ability to withstand electrical breakdown, ensuring safety and reliability in electrical applications.

-

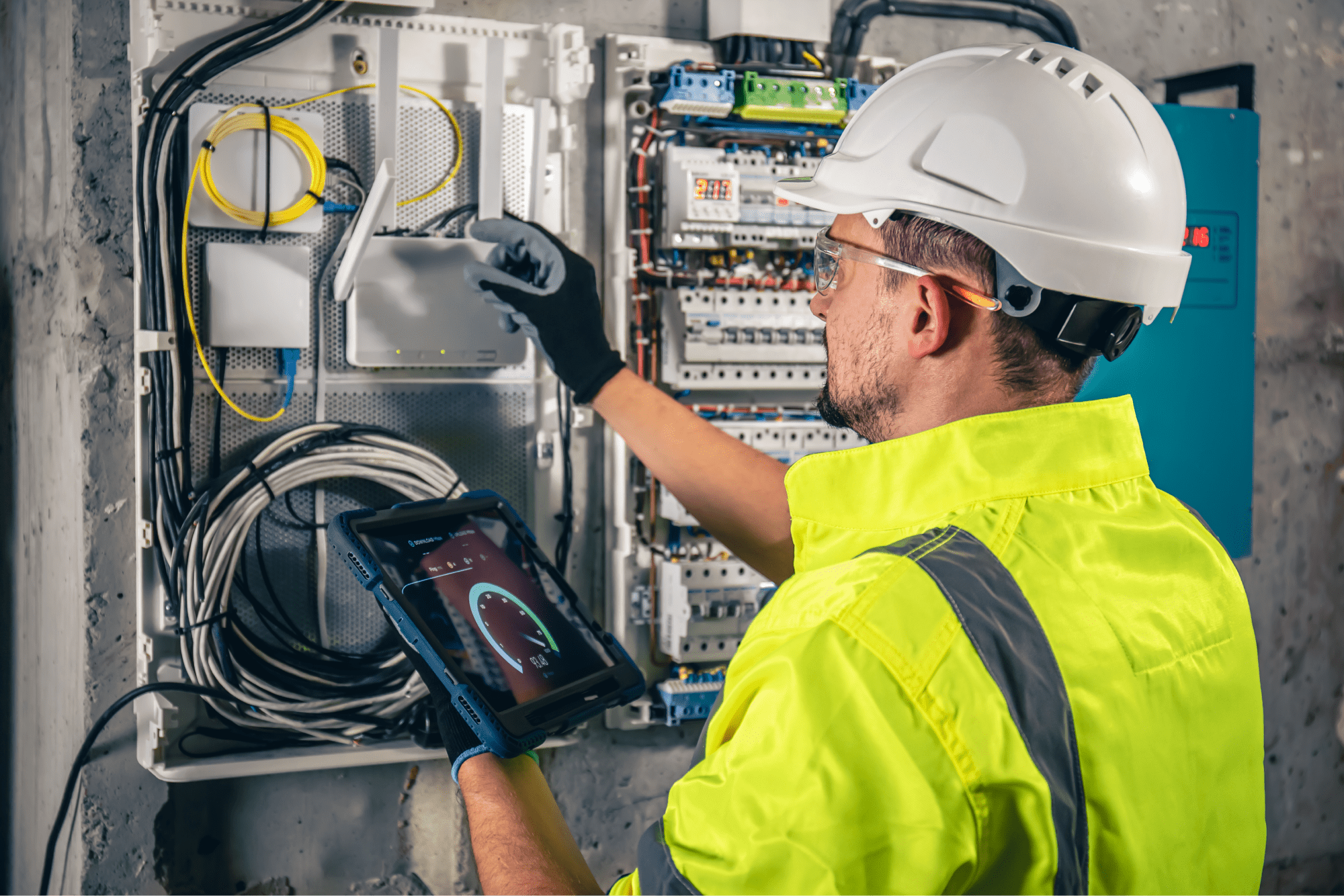

Electrical Safety Compliance Testing

Electrical safety compliance testing verifies that products meet regulatory standards and safety requirements established by organizations such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission). Compliance with these standards ensures product safety and minimizes the risk of electrical hazards.

-

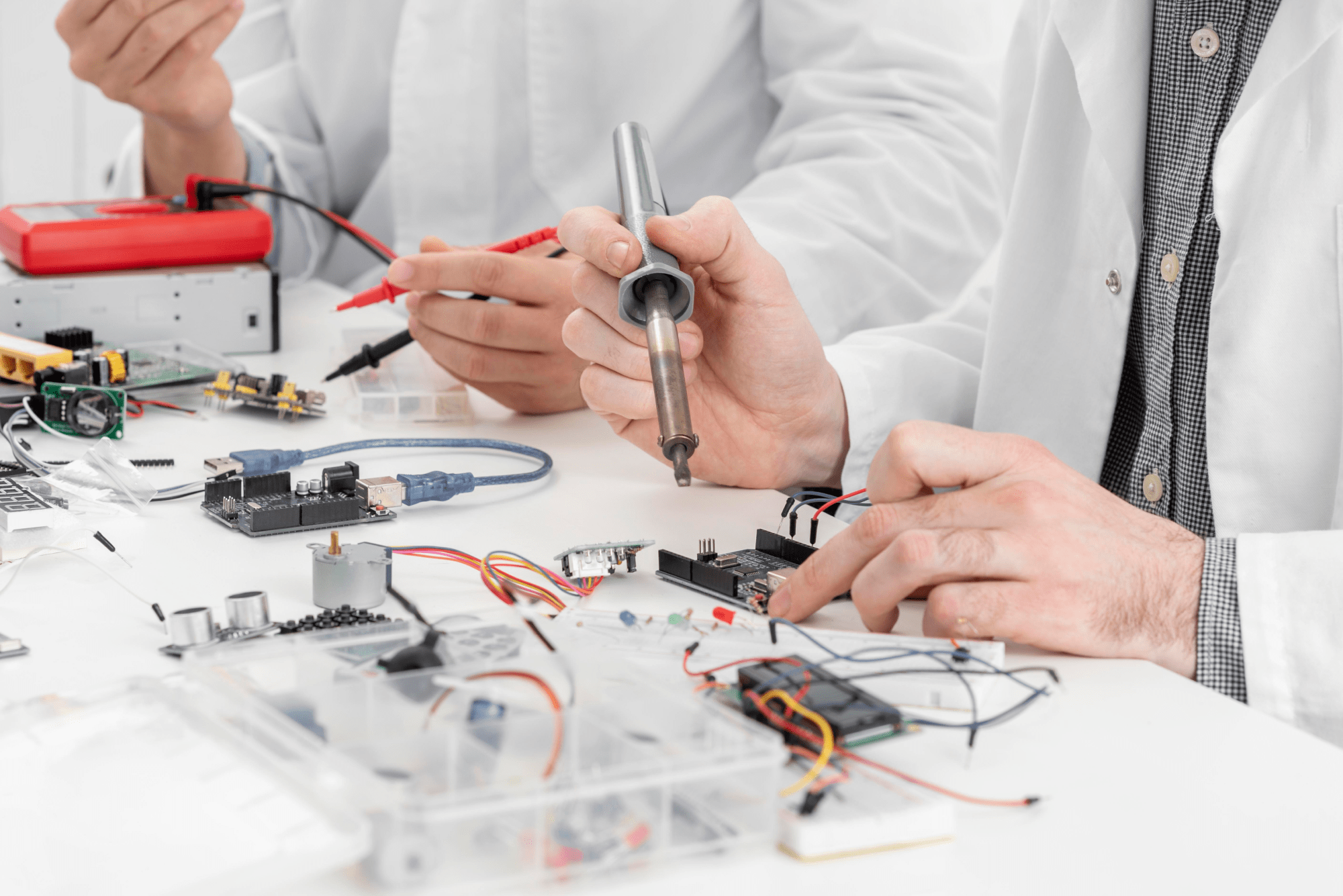

Electrical Performance Characterization

Electrical performance characterization involves analyzing key electrical parameters such as voltage, current, power, and frequency to assess the overall performance and efficiency of electrical components and systems. This testing helps optimize product design and identify areas for improvement.

-

Environmental Testing

Environmental testing evaluates the performance of electrical products under various environmental conditions, including temperature extremes, humidity, vibration, and shock. This testing ensures product reliability and durability in harsh operating environments.

-

Quality Control and Reliability Testing

Continuous monitoring of product quality through rigorous testing protocols ensures consistency and reliability in electrical products. Reliability testing assesses product performance over time to predict failure rates and improve product longevity.

Benefits of Electrical testing

-

Safety

Identifies hazards to prevent accidents.

-

Compliance

Meets legal and regulatory standards.

-

Preventive Maintenance

Detects issues early to avoid downtime.

-

Equipment Longevity

Extends lifespan of electrical components.

-

Energy Efficiency

Identifies inefficiencies for cost savings.

-

Reliability

Ensures uninterrupted operations.

-

Insurance Compliance

Meets requirements for coverage.

-

Peace of Mind

Provides reassurance about system safety and performance.

Water testing is a crucial process aimed at assessing the quality and safety of water for various purposes, including drinking, recreational activities, industrial use, and environmental

Read MorePharmaceutical raw material testing is a critical phase in the pharmaceutical manufacturing process, playing a pivotal role in guaranteeing the safety, efficacy, and quality of the final drug

Read MoreMedical device testing is a thorough process conducted to verify the safety, reliability, and regulatory compliance of medical devices. It involves assessing the performance, usability

Read MoreCosmetic testing is a comprehensive process that involves various laboratory analyses to assess the safety, quality, and sensory attributes of cosmetic products. These analyses encompass

Read MoreHerbal products, derived from plant sources, are subject to rigorous testing to ensure their safety, quality, and compliance with regulations. Testing focuses on various aspects, with a key emphasis

Read MoreEnvironmental testing is a comprehensive process designed to assess how a sample, be it a product or material, responds to various stressors and conditions that it might encounter during its

Read MoreFood Testing Is A Crucial Component Of The Food Industry, Aimed At Verifying The Safety, Quality, And Compliance Of Food Products With Established Standards And Regulations. It

Read MoreOil Testing Plays A Crucial Role In Maintaining Product Quality And Compliance With Safety And Environmental Standards. From Refining To Distribution, The Process Of Oil Testing Involves

Read MoreMechanical Testing In various industries, Mechanical testing plays a pivotal role in ensuring the quality and reliability of materials and products. From manufacturing to construction, Mechanical testing encompasses several essential components

Read MoreBuilding material testing is crucial for ensuring the quality, safety, and compliance of construction materials used in various building projects. Similar to oil testing, building material testing involves several key components

Read More