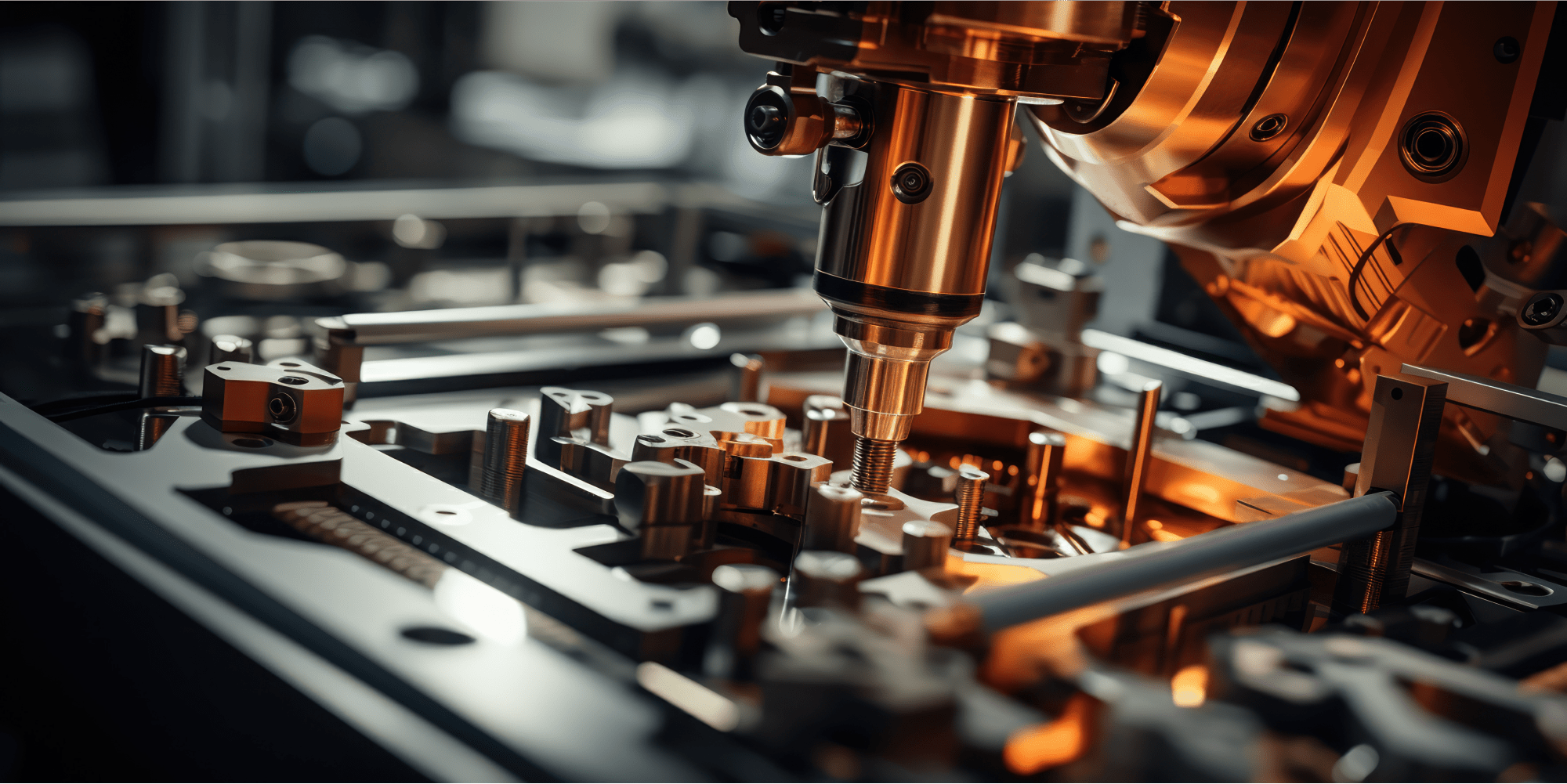

Mechanical Testing

In various industries, mechanical testing plays a pivotal role in ensuring the quality and reliability of materials and products. From manufacturing to construction, mechanical testing encompasses several essential components:

-

Material Sampling and Preparation

The initial step involves the careful selection and preparation of material samples representative of the production batch. Proper sampling techniques are employed to ensure the accuracy of test results.

-

Tensile and Compression Testing

Tensile and compression tests are conducted to evaluate the mechanical properties of materials under tension and compression forces, respectively. These tests provide crucial insights into the material's strength, ductility, and elasticity.

-

Hardness Testing

Determining the hardness of a material helps assess its resistance to indentation or scratching. Various hardness testing methods, such as Rockwell, Brinell, and Vickers, are employed depending on the material and application.

-

Impact Testing

Impact tests measure a material's ability to withstand sudden loading or impact. This testing is particularly important in applications where materials are subjected to dynamic forces, such as automotive components and structural elements.

-

Fatigue Testing

Fatigue tests assess the endurance limit of materials by subjecting them to cyclic loading. This helps determine the material's durability and resistance to repetitive stress, essential for predicting component lifespan.

-

Fracture Toughness Testing

Fracture toughness testing evaluates a material's resistance to crack propagation and fracture. It provides critical data for assessing structural integrity and designing safe and reliable components.

-

Non-Destructive Testing (NDT)

NDT techniques, including ultrasonic testing, radiography, and magnetic particle inspection, are employed to assess material integrity without causing damage. These methods are essential for detecting defects and flaws in components.

-

Corrosion Testing

Corrosion testing evaluates a material's susceptibility to corrosion under various environmental conditions. It helps assess the material's durability and suitability for specific applications, particularly in harsh environments.

-

Quality Assurance

Mechanical testing ensures that materials and products meet stringent quality standards, guaranteeing their performance and reliability in real-world applications.

-

Compliance and Certification

By adhering to industry standards and regulations, mechanical testing facilitates compliance and certification processes, enhancing market acceptance and customer confidence.

-

Risk Management

Identification of material weaknesses and performance limitations through testing enables proactive risk management strategies, reducing the likelihood of product failures and associated liabilities.

-

Operational Efficiency

Efficient testing processes minimize production delays and optimize resource utilization, leading to improved operational efficiency and cost-effectiveness.

Benefits of Mechanical Testing

-

Assured Product Quality

Mechanical testing ensures that only materials meeting stringent quality standards are used, enhancing overall product quality.

-

Regulatory Compliance

By demonstrating adherence to industry regulations and standards, mechanical testing facilitates market acceptance and regulatory approvals.

-

Effective Risk Management

Identifying material weaknesses early helps mitigate the risk of product failures, recalls, and associated liabilities.

-

Optimized Material Selection

Data from mechanical testing informs material selection decisions, improving product performance and longevity.

-

Consumer Confidence

Thorough testing builds consumer trust by ensuring products meet quality and safety standards.

-

Cost Savings

Early issue identification through testing reduces costly recalls, rework, and warranty claims, leading to significant cost savings.

-

Innovation Support

Insights from testing drive innovation in material science, product design, and manufacturing processes.

Water testing is a crucial process aimed at assessing the quality and safety of water for various purposes, including drinking, recreational activities, industrial use, and environmental

Read MorePharmaceutical raw material testing is a critical phase in the pharmaceutical manufacturing process, playing a pivotal role in guaranteeing the safety, efficacy, and quality of the final drug

Read MoreMedical device testing is a thorough process conducted to verify the safety, reliability, and regulatory compliance of medical devices. It involves assessing the performance, usability

Read MoreCosmetic testing is a comprehensive process that involves various laboratory analyses to assess the safety, quality, and sensory attributes of cosmetic products. These analyses encompass

Read MoreHerbal products, derived from plant sources, are subject to rigorous testing to ensure their safety, quality, and compliance with regulations. Testing focuses on various aspects, with a key emphasis

Read MoreEnvironmental testing is a comprehensive process designed to assess how a sample, be it a product or material, responds to various stressors and conditions that it might encounter during its

Read MoreFood Testing Is A Crucial Component Of The Food Industry, Aimed At Verifying The Safety, Quality, And Compliance Of Food Products With Established Standards And Regulations. It

Read MoreOil Testing Plays A Crucial Role In Maintaining Product Quality And Compliance With Safety And Environmental Standards. From Refining To Distribution, The Process Of Oil Testing Involves

Read MoreElectrical testing refers to a series of evaluations and assessments conducted on electrical components, systems, and devices to ensure their safety, reliability, and performance. These tests are designed to verify compliance with industry standards, regulatory requirements, and specific performance criteria.

Read MoreBuilding material testing is crucial for ensuring the quality, safety, and compliance of construction materials used in various building projects. Similar to oil testing, building material testing involves several key components

Read More